How to Produce Hydrogen Gas as Cleanly as Possible

November 13, 2024

Article body copy

As humanity works to slash greenhouse gas emissions and stem the pace of planetary warming, scientists, governments, and industry leaders are looking for low-carbon alternatives to fuel the future. Alongside renewables such as solar and wind energy, hydrogen gas is bubbling to the forefront as a fuel of choice—especially for energy-intensive processes like forging steel.

However, the carbon footprint of hydrogen gas is not necessarily as tiny as proponents argue. According to new research led by Kiane de Kleijne, who studies the environmental impacts of new technologies at Eindhoven University of Technology in the Netherlands, hydrogen’s climate friendliness ultimately depends on many factors, not least of which are where and how the hydrogen is produced.

Today, most hydrogen gas is made from natural gas using a chemical process called steam reforming. This hydrogen—known as “grey hydrogen”—is highly polluting; for every kilogram of usable hydrogen gas produced, the process spits out emissions equivalent to 13.7 kilograms of carbon dioxide. A slightly better option is “blue hydrogen,” for which hydrogen gas production is coupled with a carbon capture and storage system. This can theoretically bring emissions down to around six kilograms of carbon dioxide per kilogram of hydrogen gas. However, carbon capture technology is expensive and largely unproven; it rarely reaches even modest levels of capture.

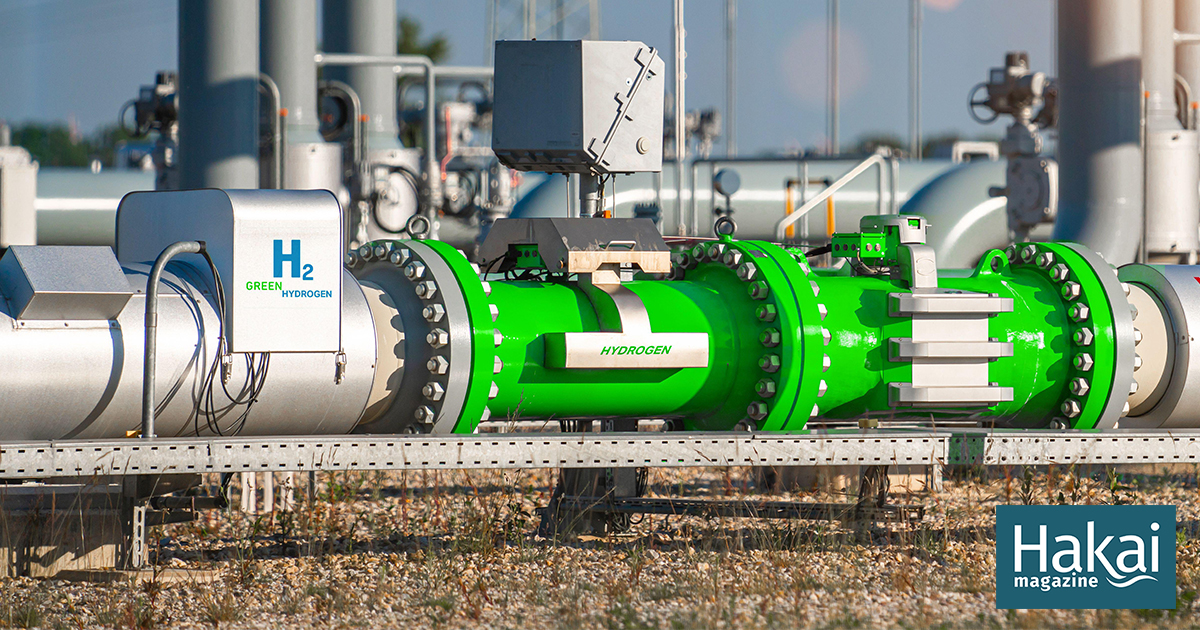

What’s really got experts’ attention is “green hydrogen,” which results when renewable energy—think solar or wind—is used to electrically split water into hydrogen and oxygen gases through a process known as electrolysis. The International Energy Agency, an intergovernmental organization, and many national governments claim that projects powered by green hydrogen produce no greenhouse gas emissions. This has spurred a flurry of subsidies from governments around the world designed to get the green hydrogen industry off the ground.

But green hydrogen isn’t free of carbon emissions just because electrolyzing water produces little planet-warming pollution. To get a true take on the environmental footprint of hydrogen gas, it’s important to consider the toll of everything else that goes into making and using it, such as building renewable energy and electrolysis infrastructure, storing the hydrogen, and shipping it around the world. These factors are collectively known as embodied emissions.

Government “policies are not designed with embodied emissions in mind,” says de Kleijne. But “if we don’t count them, we don’t see them.”

To get a better sense of the future footprint of the budding green hydrogen industry, de Kleijne and her colleagues estimated the embodied emissions that will likely result from the more than 1,000 green hydrogen projects planned to be built worldwide by 2030. The scientists analyzed each plant’s proposed design and electricity source and the emissions stemming from different methods of transporting hydrogen gas. Many projects, for instance, plan to ship their hydrogen gas by first converting it to liquid ammonia and then converting it back to hydrogen gas on the other end. But this conversion is energy intensive, and up to 30 percent of the hydrogen is lost in the process.

At best, de Kleijne and her team find that green hydrogen production creates around 2.9 kilograms of carbon dioxide–equivalent pollution for each kilogram of hydrogen gas produced. Then, depending on whether the gas is transported by pipeline or ship, add on another 1.5 or 1.8 kilograms of carbon pollution.

If these embodied emissions were included in official calculations, de Kleijne says, it would be difficult for many proposed green hydrogen projects to meet climate-related targets, such as the European Union’s renewable fuel threshold, which requires hydrogen fuels to produce less than 3.4 kilograms of carbon dioxide per kilogram of hydrogen to qualify as a clean fuel.

Mark Winfield, who studies sustainable energy and climate change at York University in Ontario, says the study reinforces the warning already being sounded by many scientists and environmentalists about green hydrogen. “Emissions can pile up through the life cycle, so we might not end up as far ahead as we thought,” Winfield says.

In general, de Kleijne says, green hydrogen will always be cleaner than grey and blue hydrogen, which also face the same challenges around embodied emissions. However, even within green hydrogen production, the analysis shows that some approaches are much greener than others.

The scientists find that the biggest differences between green hydrogen plants stem from the type of renewable energy used to power the electrolysis and how the plant is configured. Wind power is generally better than solar because building wind turbines has a lower carbon cost than deploying solar panels. And a green hydrogen plant connected to the wider electricity grid—meaning it can send any extra electricity it produces back to the grid—is better than a stand-alone facility.

Another big factor in determining the climate-friendliness of a particular facility is how far the plant is from the end user and how the hydrogen gets to them. Pipelines have the lowest emissions over short distances, while shipping is better over longer distances. “Avoiding transport is one of the most important conditions,” de Kleijne says, so building the plant near where the hydrogen will be used is key.

Zane McDonald, executive director of the industry-associated Open Hydrogen Initiative, says the hydrogen production industry is acutely aware of the need to account for embodied emissions; that’s why his group is developing a standardized method for estimating a project’s emissions. The goal, says McDonald, is to offer project leaders ways to reduce embodied emissions. There’s a strong financial incentive to do so. McDonald notes that in the United States the 45V tax credit, which supports the development of green hydrogen projects, gives more credit to cleaner projects.

“Having a policy that benefits you for investing in decarbonization measures—and erodes the competitive advantage of organizations that do not—is how we can ensure that organizations will start to make these investments,” McDonald says.

Winfield says de Kleijne’s work underlines the need to look at hydrogen production on a project-specific basis rather than making blanket assumptions about its green credentials. There will be times and places where renewable energy–powered hydrogen gas production will be a good option. But often, Winfield says, using renewable electricity to make hydrogen that will then be transported around the world just introduces extra unnecessary steps.

“We should do direct electrification where we can and only bother with hydrogen if there is a good use case that makes sense,” he says.

De Kleijne agrees. “If you can electrify something with renewable energy directly, just do that.”

Search

RECENT PRESS RELEASES

Related Post