Can H&M Decarbonize Its Supply Chain?

January 29, 2026

On an industrial park in Vietnam’s Hung Yen Province sits Bangjie, a textile manufacturer specializing in seamless sportswear and underwear. In a few short months, Bangjie will become one of H&M’s first suppliers to achieve a carbon intensity score of zero, making it a crucial player in the fast fashion giant’s bid to decarbonize its supply chain and achieve the elusive — if not impossible — goal of decoupling emissions from economic growth.

Carbon intensity is tied to the type of energy a company uses for production, measured in grams of carbon dioxide equivalent emissions per megajoule of energy. The higher the carbon intensity of a factory, the higher the emissions associated with each product. According to H&M, coal has the highest carbon intensity, followed by grid electricity (although this varies by country) and natural gas. By the brand’s calculations, renewable energy — such as wind or solar power — has a carbon intensity of zero. If the carbon intensity is zero, the brand’s emissions will also be zero, regardless of how many products it produces.

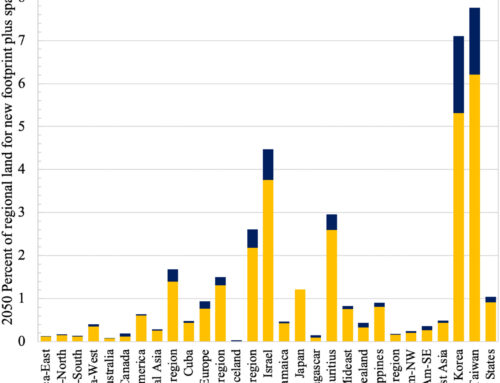

Comparing fashion’s emissions to earnings in 5 charts

What would it look like if the bottom line accounted for the true cost of fashion’s carbon footprint?

That’s the clincher: H&M set an ambitious goal in 2021 to halve emissions while doubling revenue by 2030, now just four short years away. In its 2024 full-year report, this was rephrased slightly. Now, the company says it wants to increase long-term sales growth by at least 10% per year, with an operating margin exceeding 10% and a 56% reduction in greenhouse gas emissions by no later than 2030, against a 2019 baseline. The company breaks down its near-term emissions plan into three priorities: decarbonizing production processes (currently 64% of emissions); switching to low-impact, circular and sustainably sourced materials (otherwise 17% of emissions); and extending the product lifecycle through durability and quality, which in turn should drive resale (secondhand sales currently account for just 0.6% of total revenues across H&M Group).

“We set our strategy to decouple our financial growth from resource use,” says Leyla Ertur, chief sustainability officer for H&M Group. “Our strategy is not based on reducing quantities. We would like to produce as much as we can sell.” Ertur doesn’t see H&M’s size as a foil to its goals; H&M believes its scale can help turn pilots — where many sustainability initiatives get stuck — into bona fide solutions. “We see size and reach as a way to make a real difference.”

The electrified heat pump is the result of a four-way collaboration between Bangjie, H&M, the World Wide Fund for Nature (WWF), and Apparel Impact Institute (Aii), designed to provide a cleaner and more efficient way to generate steam, a necessary component for otherwise carbon-intensive production processes such as dyeing, washing, ironing, and air cooling. The hope is that this initiative can scale across other factories and markets. “This will be the future,” says El Natour. “A fully electrified factory.”

Scaling solutions like this across the supply chain will be a long journey, requiring H&M to shift its supply chain infrastructure and create the right incentives for suppliers to drive change, not to mention a hard push on public affairs to get regulators in key production markets on side. In Vietnam, H&M says it has the beginnings of a blueprint for supply chain decarbonization, which brings all of these changes together.

While its approach to financing and scaling decarbonization is novel, H&M is not claiming to be revolutionary: its ultimate goal is “cleaner business as usual”, says El Natour, not changing the system wholesale. But is it enough? And exactly how “future-proof” is a company still intent on growth at all costs?

Identifying solutions that can scale

When it comes to decarbonizing production, H&M has two priorities, explains El Natour: reducing energy consumption by improving energy efficiency and switching to renewable energy sources. “This sounds simple, but it is not,” he says.

In 2021, H&M hired an internal team of energy engineers to shape its supplier roadmaps, whose expertise is available to suppliers for free — something H&M says has been a key driver of change because it removes a major cost barrier for suppliers and gives H&M more direct insight into decarbonization at the factory level. “We collect data from most of our factories on a monthly basis, which has helped us to create over 500 factory-specific climate roadmaps to 2030, which we track on a monthly, quarterly, and annual basis,” explains El Natour. These engineers have identified over 1,000 potential improvements to push suppliers along their decarbonization journey, some of which will take months, and some of which will take years.

When it comes to increasing energy efficiency and reducing overall energy consumption, the energy engineers have found that the “ biggest and most powerful thing a factory can do” is recycle heat by installing suction systems to catch the heat that is wasted and put it back in the system. “If you combine this with a heat pump, you have a magical way of multiplying energy,” says Kim Hellström, senior sustainability and climate manager, at H&M Group. Also on his priority list for H&M and its suppliers to invest in are heat storage, which allows factories to extract electricity from the grid at the cheapest time of day and store it until it is needed, either in bricks, sand, molten salt or water; and waterless dyeing, which has yet to hit commercial scale, but has significant potential, according to Hellström.

In Vietnam’s Thanh Thanh Cong Industrial Zone, Chinese-owned textile giant Seduno Group — which has production sites across Vietnam, Cambodia, Guatemala and, more recently, Egypt — has managed to phase out coal, with help from H&M. This was one of the decarbonization levers identified by H&M’s energy engineers, but Seduno Group says its own climate ambitions are “even more aggressive” than the roadmap H&M has set for it. In fact, just last year, it invested $2 million in an automated dyeing system to curb waste and improve worker safety in a notoriously toxic part of the supply chain.

This is an important distinction, says Kim van der Weerd, co-founder of the manufacturer-driven think tank Fashion Producer Collective. “We imagine a world where producers are co-creators of sustainability, not just implementers. That means moving away from prescribing what manufacturers should do and instead clearly articulating shared goals, while leaving space for producers to determine how those goals make sense in their own context. Trusting the people who actually do the work to figure out what makes sense on the ground is essential if sustainability efforts are going to be effective and durable.”

A few hours away in Bac Giang Province, Crystal Martin — which has been supplying H&M for 20 years and operates across 28 production sites in four countries — has also invested heavily in decarbonization, with guidance from H&M’s energy engineers. Last year, the supplier won an H&M Award for outstanding achievement in energy efficiency. Among the most effective improvements were: applying smart controls to chiller systems, increasing fresh air intake during winter months to reduce the overall electricity consumption for chiller systems, insulating pressing machines, and changing to high-efficiency motors for ventilation systems.

Despite the clear signs of progress, there’s a long way to go. “There are challenges all around us,” says El Natour. “Not everything can be solved with available technologies.”

Finding favorable market conditions

Vietnam is the world’s third largest textile manufacturing market, after China and Bangladesh. While H&M doesn’t disclose production volumes by market, Karin Lind, H&M Group’s managing director of production, says Vietnam is one of its “most important” markets with 42 suppliers and 72 production units, indirectly totaling more than 60,000 workers. This is largely down to the country’s wide-reaching production capabilities, from seamless underwear, jersey, and footwear to heavy knits, denim, and accessories.

“Vietnam is a highly capable and very mature market, with skilled workers and government ambition to continue adding value to this ecosystem,” says regional country manager Jessica Vilhelmsson. “It also has untapped potential, specifically if we can localize fabric and component production, which would allow us to make later decisions on style and fabric, and be more precise in what we produce. It would also lower costs, because importing fabric means you don’t get the full duty-free benefits of the free trade agreement between the EU and Vietnam.”

Vilhelmsson has been leading H&M’s public affairs push in Vietnam. At the end of 2024, H&M signed a direct power purchasing agreement (DPPA) with the Power Engineering Consulting Joint Stock Company 2 (PECC2), hoping to secure renewable energy for its Vietnamese suppliers despite the limited availability on the national grid. It hopes Bangjie will be one of the first beneficiaries of this.

The Fashion Pact announces new initiatives on climate and beyond

After a quiet two years, the CEO-led coalition is eyeing bold action on renewable energy, agriculture and conservation. We speak exclusively to Kering CEO François-Henri Pinault and the Fashion Pact secretary general Eva von Alvensleben.

“We believe that these agreements will be the key to private actors generating renewable energy for our suppliers, from the national grid,” says Vilhelmsson. The company had a similar successful agreement with Türkiye in 2024. “It’s a prerequisite for electrification. We have to do these things in the right order.” It’s also a priority for Vietnam, which has a target to reach net-zero by 2050, ideally with 30-60% of its renewable energy coming from DPPAs. In 2025, just over half (52%) of the electricity in H&M’s Vietnamese supply chain came from renewable sources, says Vilhelmsson.

Incentivizing suppliers to invest in decarbonization

Around 18 months ago, I heard whispers that H&M was changing its approach to price negotiations, much to the chagrin of its suppliers. It turns out those rumblings were the early teething problems associated with a new costing framework, which H&M says is a key unlock in its decarbonization journey. Rather than negotiating style by style, H&M now negotiates 80% of its orders in bulk, committing to a set number of orders six months in advance, even if the specific designs and materials are decided nearer the time. The price is based on a formula developed by Lind’s team, which accounts for material and component costs and general expenses, while ringfencing worker wages, so negotiations don’t infringe on the suppliers’ ability to pay fair wages. In theory, this means the negotiated price can also include bigger picture costs that go beyond individual products, including decarbonization investments.

“This is similar to fact-based sourcing, but really it’s new for the industry and we welcome others to join us,” says Lind, noting that the process was far from straightforward, but ultimately has made H&M’s supplier relationships less transactional, building the kind of trust needed for long-term projects like decarbonization, and helping to internalize the cost of sustainability investments, which could not be factored into product-level negotiations. “It took us many hours and many meetings to convince suppliers that this was the way forward and a win-win for both. But we went from 20,000 time-intensive negotiations to 150 [in Asia], so it makes a massive difference. And it’s been foundational to our decarbonization journey, because it gives our suppliers stability, which makes investments more possible and more secure.”

To streamline the process further, H&M has consolidated its orders to fewer, closer, and more long-term partnerships with what it calls strategic suppliers. These 28 suppliers now produce around 50% of all H&M products and are complemented by a network of around 500 suppliers, which fill the gaps in volume and capability. The closer a supplier gets to zero-carbon intensity, the bigger their orders from H&M, explains El Natour. “If we commit to the suppliers and really reward them for good performance, they are able to invest. Historically, we have seen much slower development on sustainability, but this has allowed us to leap ahead. We set pretty high expectations for our suppliers, but we also follow it up with business, commitments, and partnership. It’s about using our scale and leverage to do good.”

Unlocking finance

The relationship between fashion brands and their suppliers is typically defined by a race to the bottom: short-term, transactional relationships reinforcing global power imbalances through top-down management and purchasing practices that squeeze suppliers to no end, with a dire knock-on effect for working conditions and wages. In these conditions, few suppliers would be willing or able to make the sweeping — and often expensive — decarbonization investments needed to meet brands’ sustainability targets. The level to which H&M co-invested in Bangjie is “extremely rare” in the industry, says Aii’s chief impact officer Kurt Kipka.

For suppliers, the idea is that these sustainability investments can become a selling point in an increasingly competitive landscape. Bangjie, for example, also produces for Adidas, Calvin Klein, and Target, among others, and has already signed new production deals with Decathlon and Lululemon off the back of its heat pump and electrification. But the question of whether suppliers can charge more for this added benefit remains to be seen — at least for H&M orders, suppliers are now able to pass the additional cost of using renewable energy onto the brand (H&M says it absorbs this cost rather than passing it onto the consumer). “We’re not pushing suppliers on anything we aren’t paying for,” says El Natour.

The incentive for H&M — at least from a regulatory and reporting perspective — is less clear. While incoming sustainable fashion regulations are pushing the cost of inaction higher, the rules around carbon accounting mean that H&M cannot claim the full benefit of its investments, only the percentage that correlates to its share of production in that factory. This means other brands using the same factory can reap the rewards of improvements driven by H&M. For example, in 2024, H&M financed 23 projects through its Green Fashion Initiative, which it says led to a potential reduction of 148,000 tons of CO2 annually. However, only 67,000 tonnes were attributed to H&M Group, because their orders amounted to 45% of the factories’ total output. “I have no problem with that spillover effect,” says Lind.

As Ertur made plain, H&M is a growth company, and economic growth is its main imperative. With that in mind, its head of green investment, Ulrika Leverenz, has had to get creative in order to siphon off sufficient funds for decarbonization efforts that don’t necessarily translate into higher profits.

“The first hurdle is short-termism versus long-term value,” she says. “The world’s economic system is built on short-term profit expectations, but we know that impact investments are long-term. So, you have to separate funds that are allowed to work long term and look at new KPIs to measure the success of those funds differently: how much can this investment contribute to reducing emissions? What is the amount of water saved? How will it increase the share of recycled materials? Then, you need a separate resource to manage these funds within the organization, and tools to optimize this. We are making this transition because we want to be resilient and future-proof the business.”

The next step is for H&M to scale its learnings across other brands, factories, and markets. In May, it will host its peers at Bangjie in Vietnam, with the hope of inspiring other brands to make similar investments. “We share everything we have done, even the bad things,” says Hellström. “We don’t want other brands to make the same mistakes. We can’t afford to slow down this transition.”

Search

RECENT PRESS RELEASES

Related Post