Old Turbines, New Tricks: How Retrofits Drive Efficiency and Extend Lifespans in Power Gen

December 1, 2025

By retrofitting aging turbines with modern control systems, power generation companies are extending equipment lifespans, enhancing operational efficiency, and tapping into robust global support networks—transforming existing assets into high-performing components of a modern energy portfolio.

As governments and citizens around the globe call for increased power generation via renewable energy, demand for more green electricity is expanding at an incredible pace. Electric vehicles, an increased need for computing power to feed artificial intelligence (AI) data centers, expansion of smart technologies as a result of 5G networks, and more are driving a global need for rapid energy production. To meet this need, utilities and other power generators are exploring many new options for producing electricity.

One of the most common, longstanding, and reliable forms of green energy generation is the wind turbine. Wind generation technology has been around for decades. It is well understood, reliable, and, when engineered and operated properly, tremendously efficient and cost-effective. As a result, many energy producers are expanding their generation portfolios with wind assets. However, building new turbines is expensive, complex, and time consuming, so many companies have turned to acquiring existing assets as a fast way to increase green energy output.

While expanding a green energy portfolio with existing wind assets is both efficient and effective, it does come with challenges. Many of the wind turbines acquired will be decades old, and as a result they will be difficult to monitor and control because their legacy control systems and internal components will not perform to modern standards. Fully replacing a legacy turbine is not only expensive; it is often impossible, as changing regulations have led to complex permitting requirements. Moreover, replacing a turbine means long downtime and lost production (Figure 1).

|

|

1. When acquiring existing assets, legacy control systems will often not perform to modern standards, but a control system retrofit will typically provide more reliable performance and increased revenue. Courtesy: Emerson |

Fortunately, there is another way to drive increasing value from legacy wind turbines—a turbine control system retrofit. When performed by a supplier with deep wind industry expertise, this type of retrofit can bring aging equipment up to the best modern standards quickly, resulting in more reliable performance and increased revenue for a fast return on investment (ROI).

What Is a Retrofit?

A team performing a wind turbine retrofit refits an existing turbine with new blades, as well as a new generator, converter, control system, and pitch system. Typically, as part of the retrofit, most companies will also opt to add a condition monitoring system, as it can be installed quickly and easily during construction to deliver even more benefits and faster ROI. All that is left from the old turbine is the core infrastructure—everything else is replaced with modern components.

As complex as the process sounds, highly experienced suppliers can perform a control system retrofit in one or two days for each turbine. These providers use out-of-the-box solutions predesigned for the most common wind turbine models across nearly every original equipment manufacturer (OEM). The new units are plug-and-play and are connected using adapters that plug directly into the legacy connectors in the existing cabinet. Neither the cabinet nor its wiring needs to be replaced (Figure 2).

|

|

2. Out-of-the-box control retrofit solutions are predesigned for the most common wind turbine models across nearly every original equipment manufacturer, unlocking a wide array of new capabilities to drive production and performance. Courtesy: Emerson |

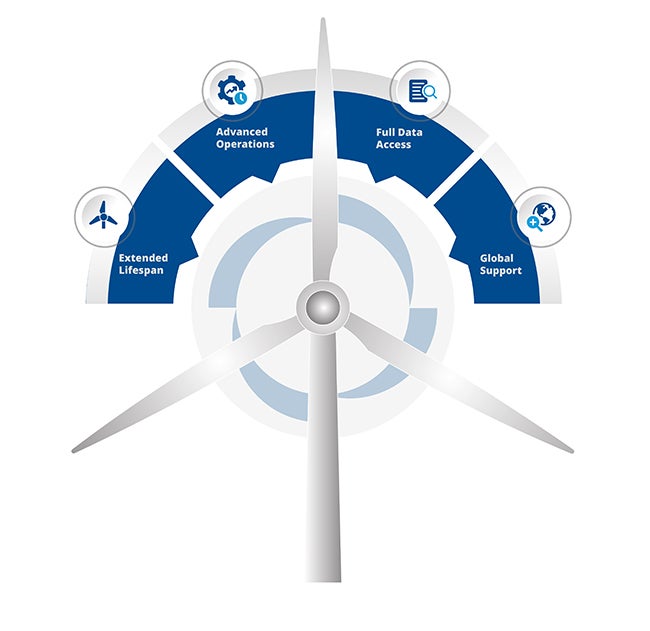

Once the new control system and condition monitoring solution are in place, operations and maintenance teams can unlock a wide array of new capabilities, empowering them to drive production and performance to levels unattainable with legacy control solutions. Ultimately, companies see at least four key benefits after a control system retrofit: improved service and longer lifetimes, more advanced operations, more effective failure modes and effect analysis (FMEA), and global support.

Improved Service and Longer Lifetimes

Typically, power generators perform a control system retrofit to prolong the life of their wind turbines while simultaneously ensuring they maintain the best possible operations. Often, companies do not have expert personnel onsite to accomplish this, so they rely on manufacturer support. However, when long-term service agreements (LTSAs) end, the owner takes control of the turbine, and support from OEMs is often limited and expensive.

Turbines operating outside of LTSAs are usually in the lowest priority group for help from the original manufacturer. If it takes the support team weeks or months to react to a service call and an asset is down all that time, the result can be significant lost production and revenue.

When a company refits its turbines with new technology via a control system retrofit, they have the option to receive service and support from the new manufacturer. Not only does the operator have someone to call to navigate complex issues, but if the control retrofit was performed by a provider with deep industry expertise, they will also have access to fast, effective response to get their turbines back in operation as quickly as possible.

Another complexity of operating turbines outside of an LTSA is the difficulty of accessing spare parts. Typically, spare part prices increase dramatically when turbines reach end-of-life. In fact, for the oldest turbines, some spare parts may even be unavailable. With a retrofit, teams regain access to available, affordable spare parts to help ensure critical assets are not standing still while maintenance waits on parts delivery.

More Advanced Operations

When teams retrofit the hardware in their turbines, they add modern software applications and turbine logic. The result is an ability to leverage more advanced operations to run the turbines better in a wide variety of conditions. In many cases, operations teams can drive more annual production from the same turbine.

Power boost functions available in modern turbine control systems can increase the output of the turbine during specific periods of operation. Using the new control logic, operations teams can compare existing operational models to design new strategies that optimize how they use the turbine. For example, using such models the team may find opportunities in the wind spectrum where they can boost a 2-MW turbine to 2.1 MW. Modern control technology provides visibility into these opportunities to help teams design such a strategy, without risking damage to the turbine’s components.

In addition, many operations teams running legacy turbine control systems find that their assets do not perform well because original site assessments were not properly performed. As a result, yaw and pitch misalignments are common, as is overspeed on turbines not designed for the actual conditions at the site.

Installing new control logic can help navigate these challenges. The best retrofit implementation suppliers have been part of the design of turbines for over 40 years. They can help operations teams perform load calculations on turbines to determine exactly how much load the asset can handle in each operational state before overspeed. Moreover, these teams can use modern logic in new pitch systems to angle blades correctly to ensure they aren’t misaligned for each operational state, decreasing wear and tear on components.

Another potential for improved performance via a control system retrofit comes from enhanced yaw alignment. Today, about 90% of turbines are not properly aligned toward the wind, creating more load on the turbine, which wears out components and reduces annual production. Modern logic and control applications enable many operations teams to gain 2% to 4% more annual production, while simultaneously adding up to 10 years onto the life of the turbine’s main components via improved control strategy.

More Effective FMEA

When wind turbine owners inherit new turbines but keep the old controls, they typically lack access to the data and knowledge they need to understand what is happening internally. For example, an operations team may not have clear visibility into how the logic is working in a converter, or when and why the turbine is pitching in certain conditions. Or, the team may be receiving alarms, but they do not understand why or what to do, so they just reset the turbine or ignore the alarm. Most often this happens because logic was built over years into an OEM control system that operates as a black box, with limited or no access to the necessary information to understand what is happening.

When teams implement a control system retrofit from a provider with deep industry expertise, the new control logic provides full access to control system data, making it easy for teams to understand what is happening in every operational mode, and to make changes to improve performance over time. Moreover, such solutions are designed with embedded FMEA data to simplify the operation and maintenance of turbines.

For example, if a turbine with a new, best-in-class control system and condition monitoring software sends a temperature sensor alarm, it provides a link the operator can follow to immediately identify the root cause of the problem. Moreover, the system will also offer decision support—providing recommendations of what is happening and what the user can do about it. In many cases, built-in FMEAs can help the team change the operation state of the turbine to derate it or take it out of production until a fix can be implemented. Instead of running to failure, teams can plan their outages using predictive methodologies, tracking and trending operation to perform proactive instead of reactive maintenance.

Global Support

One of the key benefits of a control system retrofit is that power companies gain access to a global, one-stop shop for their remote operations centers, all the way to the inside of their assets. When a company implements a control system from a solution provider with deep industry expertise, they also gain access to a wide variety of additional software: park control solutions, remote operations solutions, asset performance management, maintenance and diagnostic software, green energy supervisory control and data acquisition solutions, and other technologies in the solution provider’s green energy solutions portfolio.

As companies start to build synergy of solutions across their enterprise, they begin working toward a boundless automation vision of seamless data mobility from the intelligent field, through the edge, and into the cloud. Cross-functional teams gain nearly limitless access to the data they need to make more effective business decisions, and the organization can leverage a single point-of-contact at the solution provider, spanning a global network for any support the company may need.

Modernized Technology Drives Improved Operation

Facing an increasing need for green energy generation alongside a workforce shortage driving operation and maintenance teams to run as lean and remote as possible, power producers can no longer afford to run aging, failing assets that force personnel to continually head into the field to service stopped turbines. Control system retrofits not only bring back the reliable operation of new turbines, but also unlock the modern infrastructure necessary for the advanced control strategies that let teams operate to modern standards. With solutions available for nearly every type of turbine in operation today, there has never been a better time to modernize the assets that have been reliably generating renewable power for decades.

—Thomas Andersen is vice president of renewable technologies for Emerson.

Search

RECENT PRESS RELEASES

Related Post