Strategic model for integrating biogas a framework for sustainable energy integration in agro-industries

December 28, 2024

Abstract

The framework of the methodology presented in this study is an effort to integrate and optimize the agro-industry sector, especially energy in biogas. In this study, the technique of the system in functional analysis is shown systematically to translate various energy requirements in the factory as criteria for performance and functional design to be integrated, optimized, and energy efficient. The case study results indicated that biogas power plants, with a capacity of 1.5 MW, can produce around 13,140 MWh per year. The annual return on investment (ROI) is around 37.13%. With this ROI value, the payback period is 31 months. The overall reduction of greenhouse gases is approximately 77,826 tons CO2 eq/year. The potential value of carbon trading is about USD 3,113,040 per year. This strategic model presents a novel approach by integrating biogas energy production with a customized wastewater treatment system adapted to biodigesters’ effluent characteristics. It offers a sustainable, economically feasible, and scalable solution, combining resource recovery, waste minimization, and potential for carbon trading into a unified system. The novelty of this research lies in maximizing the utility of biogas plants by efficiently treating and reusing wastewater, creating a closed-loop, zero-waste process. Future research on hybrid systems integrating Biogas power plants by focusing on efficiency optimization, economic feasibility, environmental impacts, and innovative approaches like AI and blockchain could make the hybrid system a more robust, scalable, and sustainable solution. Thus, the framework based on the results of this study finds tools that can maximize and integrate energy sources, especially biogas, in the agro-industrial sector.

Introduction

Climate change is still a significant concern in both global and national contexts. The international community has committed to reducing greenhouse gas (GHG) emissions. In 1992, it was codified in the United Nations Framework Convention relating to the ongoing existence of Climate Change1,2,3. Through Law No. 6 of 1994, Indonesia has ratified the UNFCCC. Then, in Indonesia, through Law No. 17 of 2004, this framework was followed by the Kyoto Protocol in 1997, which was adopted ten years later. The law affirms that as one of Indonesia’s critical players involved in addressing the challenges posed by climate change, its extensive forests are vital for carbon sequestration, including its natural resource potential. In 2011, in the Presidential Decree contained in number 61 of 2011 related to the Planning of National Action on GHG Emission Reduction (known as RAN-GRK), the target of reducing GHG emissions by 26% by 2030 compared to the baseline was proclaimed4,5,6. RAN-GRK requires every province in Indonesia, including stakeholders and local governments, to actively contribute to local actions by implementing a participatory approach.

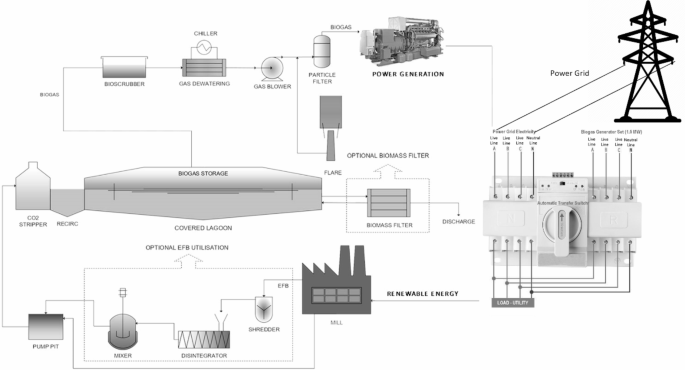

Biogas power plant is a system that converts biogas into electrical energy. Biogas can be defined as a mixture of methane gas (CH4) and carbon dioxide (CO2), which is initially sourced from the anaerobic fermentation process (without oxygen) of organic matter by various types of microorganisms7,8,9. This process can occur in a biogas digester, a closed reactor designed to facilitate the fermentation of organic matter such as livestock waste, plant residues, or household waste. This is summarized in Fig. 1.

In recent years, renewable energy has become a significant focus for many countries in their efforts to reduce dependence on fossil energy sources and reduce carbon emissions. One form of renewable energy that is becoming increasingly popular is biogas, which can be produced from organic waste, such as animal manure, agricultural waste, and household waste10,11,12. Biogas Power Plant is a technology that utilizes biogas to generate electricity13,14,15,16. This article will compare the electricity used by Biogas power plant and electricity from the State Electricity Company (SEC) in Indonesia, focusing on savings and efficiency.

Digesters that produce a variety of biogas can be used by humans as fuel for power plants so that they can produce electricity. Biogas power plants can be used on a small scale for the needs of households or local communities17,18,19,20 or on a large scale to meet industrial or commercial electricity needs.

The implementation of a hybrid energy strategy that combines electricity from SEC with biogas power plants is one of the solutions to overcome the instability of electricity supply, especially in island areas that are far from energy distribution centers21,22,23. This hybrid system not only improves the stability of the electricity supply but also supports energy sustainability through utilizing local resources, such as agricultural and livestock waste.

However, until now, there has been a need for adaptation from the framework to integrate energy into the agro-industry. This research aims to fill in the gaps in knowledge based on the following questions:

-

(1)

How to systematically identify leverage points in an agro-industry for simultaneous integration of biogas energy and on-grid power energy source;

-

(2)

How to integrate biogas energy in a way that optimizes the overall energy efficiency of the industrial plant.

This research mini article was made to produce a conceptual framework that allows simultaneous optimization in factories in the agro-industrial sector, especially hybrid biogas energy. This research sustainably obtains energy availability to process and reduce energy needs locally and internationally. The study will discuss the implementation of biogas-based hybrid energy projects, explore the hybrid system models used, and analyze the results, including cost savings, contribution to carbon emission reduction, and the resulting socioeconomic impact on local communities.

Materials and methods

Conceptual framework integrating hybridized biogas energy

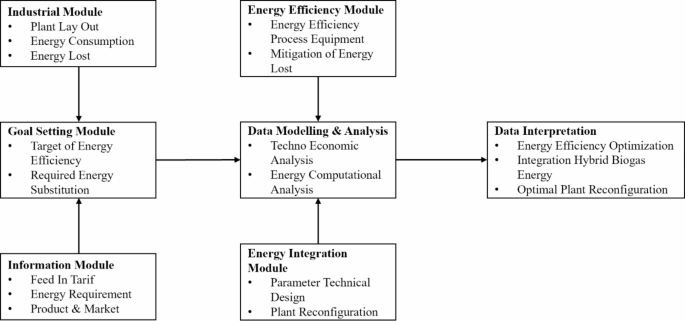

Developing models of activities to optimize energy in industrial plants, especially hybridized biogas energy, has become a conceptual framework for research. This framework flow is implemented before investment decisions in renewable energy are implemented. This is summarized in Fig. 2.

The development of seven modules as a reference in the conceptual framework24,25,26:

Industrial module, goal setting, Modules from various types of industries, in setting the objectives of the module, modules used as information, modules as a reference for energy efficiency, modules as the integration of energy, modeling on various data, analysis on modules, and data interpretation in modules. The conceptual framework design is modeled almost the same as the methodology by27,28,29, namely to model the existence of an effective and efficient information process in the financial supply chain in the industrial sector5.

A detailed description of each module with practical illustrations of the agro-industrial plant follows.

The industrial plant module

If the purpose of re-registration has been determined, which is then documented, the next is the module stage of the industrial factory as a framework for all human activities in the factory5. The objectives of this module are (a) to understand and map the layout of a factory as the most important unit operation; (b) to determine the form of the type of energy in the hydro, heat, or electricity plant; (c) Measuring the use of energy in water, heat, or electricity generation; and (d) Determining energy losses for hydro, heat, or electricity generation.

Table 1 shows historical data on the percentage of energy distribution for different unit operations in an agro-industry plant. Please note that the exact percentages can vary depending on the specific plant’s configuration and energy efficiency, but these data can give a general idea of the same process.

Information module

If the operation process in all units related to energy sourced from the plant has been analyzed and documented, the next stage is the information module contained in the framework25,30,31,32. Data regulations can interpret this to external information sources to optimize hybrid biogas efficiency and energy integration. This is related to (a) the existence of feed-in tariffs on types of renewable energy at the plant operation site, (b) the existence of essential needs related to theoretical energy, which is sourced from the difference in unit operation (UO), including in the layout of the plant; and (c) the existence of knowledge products and markets with the aim of UO differences about the efficiency of energy. The importance of product and market knowledge is very urgent as optimizing the efficiency of energy contained in the factory is carried out to replace UO, which is no longer an energy-saving technology.

The goal-setting module

The first stage is the module that sets goals as a framework33,34,35,36. This step determines the energy efficiency target and the need to disconnect from the percentage level in energy substitution, including biogas energy. Generally, these decisions are used in projects related to operators and energy engineers in the plant management sector. Improvement of energy efficiency and replacing energy used in gas energy are goals for agroindustrial crops. The purpose of this module is to create a guide to the entire process.

The energy efficiency module

The methodology of the energy block guides this study based on previous research by Baniassadi et al. (2015) and Jha & Tripathy (2021). So, the second stage, a module, is related to energy efficiency as a framework. This stage is associated with a person’s activities in conducting audits and optimizing the level of energy efficiency in the factory area. Consideration is made in this module to maximize energy efficiency, including using various tools in the energy-saving flow, minimizing the occurrence of energy shortages from units in water, heat, or electricity plants, and integrating unit operations on water, heat, or electricity plants. In all these aspects, the researcher considers the days for operating units in water, heat, or electricity plants related to the factory layout, especially in agro-industry. Then, it is described in the discussion of this research. After that, optimization was carried out on the system guided by the theory of30, (Srivichai and Chavalparit 2024)37, with a simultaneous anaerobic bioreactor unit based on the theory from (Vargas-Estrada et al. 2024).

The energy integration module

The third stage is to optimize energy efficiency as a framework. This stage is urgent in integrating the energy system, especially biogas energy37,38,39,40. Researchers have considered the flow at this stage, including reconfiguration in the factory, geographical parameters, and technical design specifications. The flow of methodological work development is in Fig. 2. Figure 2 consists of activities (illustration in the middle square in Fig. 2), inputs to perform activities (illustration in the left square in Fig. 2), and output from the completion process in each activity that has been carried out (illustration in the correct square in Fig. 2). Suppose there is a failure to achieve the previously set goals. In that case, it is necessary to repeat the application of the feedback loop in certain activities until the goals can be achieved efficiently and optimally.

Data modeling and analysis module

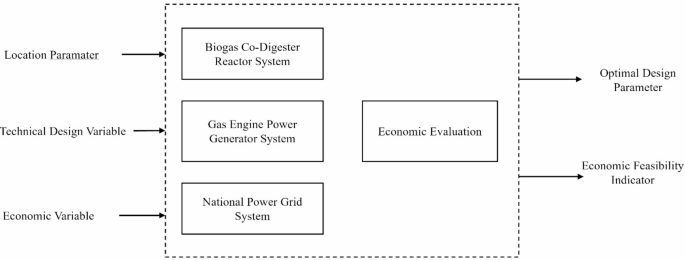

The third stage is a module on modeling and data analysis as a framework. This is a stage that is so urgent in calculating and collecting research data that has been carried out. The analysis carried out by the researcher is related to the feasibility of techno-economy and energy analysis on computing tools. System Advisory Model (SAM)30, performance models, and financial models are the researcher’s considerations in this research case study. However, SAM is not used as a performance consideration, and estimated energy cost expenditure refers to the installation costs, parameters, and operation of the model design as inputs to the model41. The researcher used SAM in this study as a cost and performance analysis related to renewable energy projects assisted by computer models in Fig. 3 below.

Figure 3 above shows the input parameters for the biogas energy model. Resource data from biogas energy at this research site is already available at SAM. However, determining the biogas bioreactor module and the ATS parameters depends on the researcher’s experience. The first parameter in system design is related to the alternating current in the air conditioner, the land use, the configuration for electricity, and the size of electricity. The number of cases is low because the location on the system is empty. The selection of the period for a quarter of a century is in line with the next module of the biogas reactor. System-based cost design refers to data obtained from the local market. From the past until now, there have been no incentives nationally for the benefit of the commercial biogas system. Electricity tariff costs refer to Indonesian regulations, especially from the Indonesian Public Utilities Regulation Commission. The determination of the electricity load refers to the rate of accumulation of 8% in 12 months, which aligns with the projected growth level of electricity demand nationally.

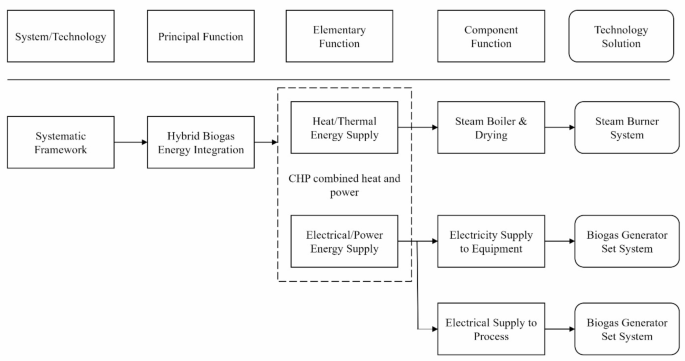

The data interpretation module

The fourth stage is a module on data interpretation as a framework. This stage urgently translates the theoretical results to the recommendation for all vis-à -vis plants to optimize energy efficiency, integrate energy, especially in hybrid biogas, and reconsider the plant, as summarized in Fig. 4. The researcher used the Functional Analysis System Technique (FAST) to measure this study’s framework30,42. FAST functions in understanding the process of each component thoroughly from the framework, so it is expected to provide value related to optimization for energy efficiency and integration of solar energy at the plant site that produces bioethanol. The advantage of using this approach is that FAST is proven to help humans solve research problems in a clear, systematic, effective, and efficient manner related to many functions in the system so that it gives rise to a logical relationship between functions and technological solutions. FAST is illustrated in the results and discussion section.

Automatic transfer switch (ATS) module

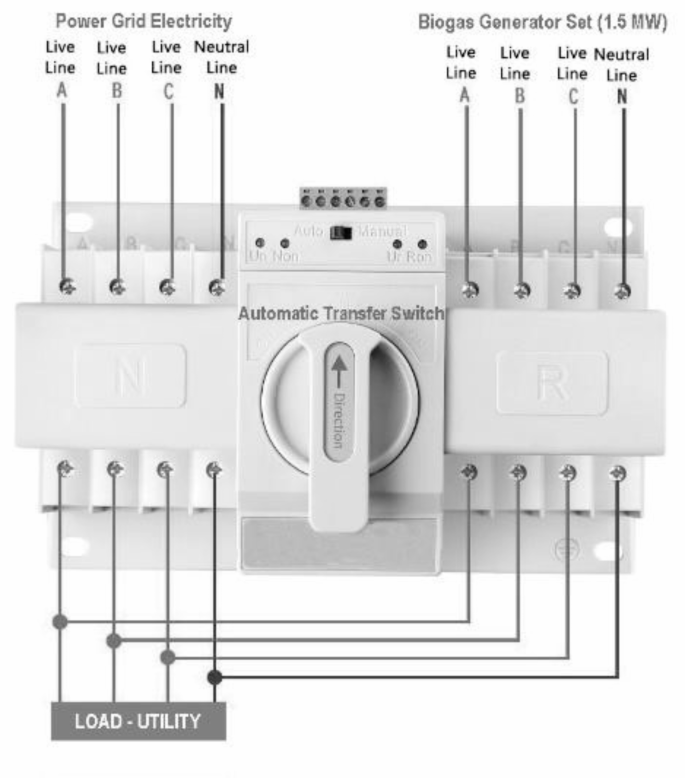

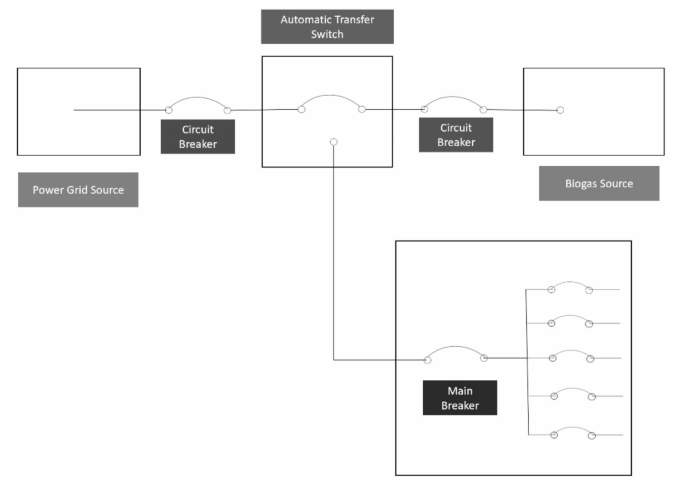

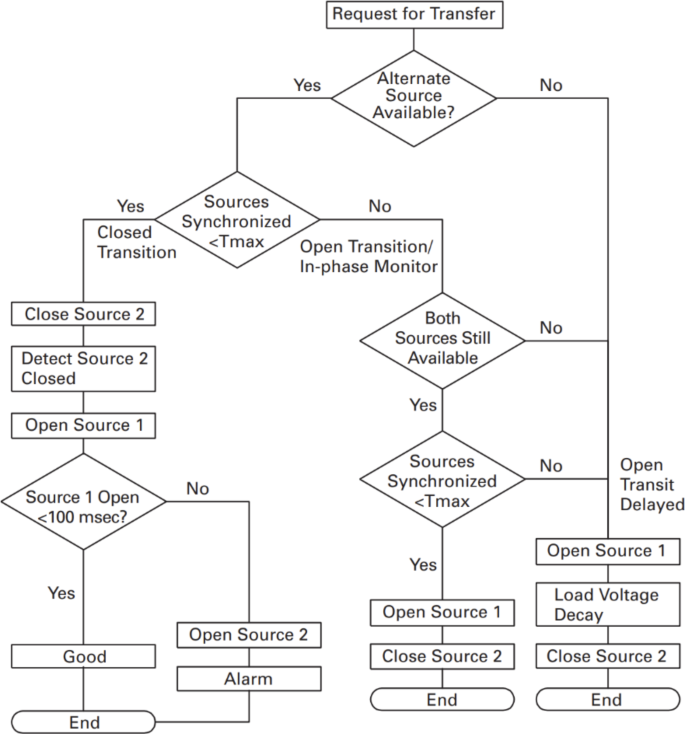

The technology used for the hybrid synchronization of electrical energy13,43,44 between the Biogas Power Plant and the SEC network involves various modern systems and components. Synchronization in this hybrid energy system is essential to ensure that the electricity generated from the Biogas power plant can run parallel with electricity from SEC without disturbing grid stability. This is summarized in Fig. 5.

This study uses an ATS to auto to switch between the electricity supply from the Biogas power plant and the SEC; automatically, if electricity from the Biogas power plant is disrupted or the capacity decreases, the ATS will divert the electricity supply to the SEC network without cutting off the electricity flow to the production system. Once the production from the Biogas power plant is stable, ATS will return the electricity supply from the Biogas power plant to the production system. This is summarized in Fig. 6.

A synchronizing panel is also used in the system application. A panel regulates the synchronization between the electricity flow from SEC and the biogas generator, especially in applications where both power sources must work simultaneously or the load must be distributed between them. In Fig. 7, the panel has various gauges and controllers to ensure the two power sources’ voltage, frequency, and phase sync.

Figure 8. Show a synchroscope, a tool used in an electric power system to synchronize a generator or alternator with an existing power grid. The synchronization process is essential to ensure that the generator’s frequency, voltage, and phase angle to be synchronized are in line with the network so that safe and stable operation can be achieved.

Result and discussion

Although Biogas power plant requires a considerable initial investment to build infrastructure, such as biogas digesters and power generators, this investment can provide significant savings in the long run. Biogas power plant users can enjoy cheaper or even accessible electricity once the initial investment cost is covered.

Meanwhile, SEC electricity requires constant costs during use, with rates that can fluctuate according to government policies and fluctuations in fuel prices. Therefore, for those with access to abundant organic matter sources, a Biogas power plant can be a more economical option in the long run.

The initial investment in biogas power plant

The initial investment in constructing a Biogas power plant consists of several main components, as shown in Table 2. The following is a historical of the initial investment cost for a Biogas power plant with a capacity of 1.5 MW.

Table 3 shows investment cost components based on existing market prices and historical data from previous Biogas power plant projects. As shown in Table 2 following;

Biogas power plant operational costs

In this study, the operational costs of Biogas power plant were found to include; maintenance and maintenance of equipment (e.g., generator machines, gas treatment systems), labor costs to run daily operations, raw material costs (although biogas usually comes from organic waste, there are still collection and processing costs)45,46,47. What can be conveyed in Table 4, annual operating costs are usually estimated at around 3–5% of the total initial investment cost.

Revenue and savings

Biogas power plant, with a capacity of 1.5 MW, can produce about 1.5 MW × 24 h × 365 days = 13,140 MWh per year, assuming operating 24 h a day all year round.

Electricity tariffs in Indonesia vary, but to calculate the Return on Investment (ROI), we can use an average industrial electricity tariff of around USD 0.10 per kWh (USD/kWh). Equation 1, the potential annual revenue from electricity sales or electricity cost savings is:

ROI

Equation 2. ROI is a measure of performance to evaluate the efficiency or profitability of an investment and to compare the efficiency of several diverse investments48,49,50. ROI is calculated by comparing the profit or profit earned from the investment with the cost invested. ROI is expressed as a percentage and shows how well an investment makes a profit relative to its price.

Formula to calculate ROI namely:

ROI = 37.13%

This means that the annual ROI is around 37.13%. With this ROI value, the payback period can be calculated by the following formula;

The conclusion that can be drawn is that the initial investment for a 1.5Â MW capacity Biogas power plant ranges from USD 2,950,000 with annual operating costs of around USD 180,000. The ability to generate yearly income/savings from electricity generated is estimated at USD 1,314,000. The annual ROI obtained is around 37.13%, with a payback period of around 2.7 years. In the long term, a Biogas power plant, with a capacity of 1.5Â MW, can be a profitable investment in terms of saving electricity costs and contributing to carbon emission reduction and environmental sustainability.

The estimated GHG reduction from Biogas Power Plants with a capacity of 1.5Â MW can be calculated based on greenhouse gas emissions avoided by replacing fossil fuel power plants (e.g., coal or natural gas) with renewable energy such as biogas.

Estimated emissions avoided by biogas power plant electricity production of 1.5Â MW

Equation 4. To calculate the emissions avoided51, it must first calculate the amount of energy produced by a 1.5 MW Biogas power plant in a year. Assume that the Biogas power plant operates 24 h a day and 365 days a year:

Estimated greenhouse gas emissions from fossil-based power plants

The average CO2 emissions from fossil fuel power plants (mainly coal) are about 0.9 tons of CO2 per.

MWh of electricity produced. Equation 5. Therefore, CO2 emissions that can be avoided by replacing fossil fuel plants are;

Reduction of methane (CHâ‚„) emissions from waste treatment

In addition to reducing emissions from fossil electricity substitution, Biogas power plants also reduce methane (CHâ‚„) emissions (Carchesio et al., 2020; Olatunji et al., 2022), which is a greenhouse gas with a global warming potential (GWP) twenty-five times greater than CO2. The organic waste treated in the biodigester produces biogas, mainly methane. If organic waste decomposes naturally without being treated in a biodigester, methane will be released into the atmosphere.

Estimated reduction of methane emissions

Estimate based on average assumptions: One m³ of biogas contains about 60% methane and produces 2 kWh of electricity, as summarized in Eqs. 6, 7, 8, 9.

-

The volume of biogas produced per year:

-

The weight of methane per 1 m³ CH₄ weighs about 0.67 kg.

-

Global Warming Potential (GWP) CHâ‚„ .

Because methane has a global warming potential as much as twenty-five times greater than CO2 (Lerdlattaporn et al., 2021; Singh et al., 2021), then the determination of the reduction of methane emissions is as follows:

Total GHG emission reduction

Equation 10. The total reduction in greenhouse gas emissions from Biogas power plants consists of reducing CO2 emissions from fossil-based power plants and reducing methane emissions from waste treatment can be estimated as follows:

Total GHG Reduction = 11,826 tonnes CO2/year + 66,000 tonnes CO2 eq/year

Total GHG Reduction = 77,826 tons CO2 eq/year

The conclusion is that a Biogas power plant, with a capacity of 1.5Â MW, can reduce greenhouse gas emissions by 77,826 tons of CO2 equivalent per year. This reduction comes from 11,826 tonnes of CO2 per year avoided from fossil fuel-based electricity substitution and 66,000 tonnes of CO2 equivalent per year avoided from treating methane generated from organic waste. This potential emission reduction shows that the Biogas power plant produces renewable energy and contributes significantly to climate change mitigation.

Total GHG emissions

To calculate the potential value of carbon trading from a 1.5Â MW Biogas Power Plant, we need to correlate the amount of GHG emission reductions calculated pre-calculated with the carbon price in the carbon market. Based on previous calculations, a 1.5Â MW Biogas power plant can reduce emissions by 77,826 tons of CO2 equivalent (CO2 eq) per year. These figures include:

-

11,826 tons of CO2 eq from fossil fuel-based electricity substitution.

-

66,000 tons of CO2 eq from reducing methane emissions (CHâ‚„) through waste treatment.

Carbon prices in the carbon market

Carbon prices in international markets vary depending on regions, regulations, and carbon trading schemes. Carbon prices are currently in the range of USD 30 to USD 50 per ton of CO2 eq, with the average price often used for calculations being around USD 40 per ton of CO2 eq.

Calculation of potential value of carbon trading

Using an average price of USD 40 per ton of CO2 eq, we can calculate with Eq. 11. the potential value of carbon trading is as follows:

Potential Revenue Carbon Trading = 77,826 tonnes of CO2 eq /year × USD 40 per ton of CO2 eq

Potential Revenue Carbon Trading = USD 3,113,040 per year

It can be concluded that the potential value of carbon trading for a 1.5Â MW capacity Biogas power plant, with a reduction in emissions of 77,826 tons of CO2 equivalent per year and an average carbon price of USD 40 per ton of CO2 eq, is around USD 3,113,040 per year. This revenue potential shows that the Biogas power plant not only generates electricity from renewable energy but can also generate significant additional revenue through carbon trading schemes, providing financial incentives while supporting the global reduction of greenhouse gas emissions.

Weaknesses of hybrid systems and solutions

Hybrid systems that combine Biogas power plant and SEC’s grid have challenges, such as dependence on organic waste supply, inconsistent water quality, high initial costs, and maintenance challenges17,52,53,54,55,56. However, with the right strategy—such as diversification of raw material sources, effective maintenance systems, the integration of energy storage technology, and collaboration with various parties—these weaknesses can be minimized. The result is a more sustainable, efficient system with significant environmental and economic benefits.

Dependence on organic waste supply

Biogas power plants rely heavily on the constant availability of organic waste to produce biogas. Fluctuations in the supply of raw materials (whether using agricultural or livestock waste) can decrease biogas production, thereby reducing the efficiency of power plants.

The commonly used ways to deal with this can vary empirically and literally. They are starting from diversifying sources of raw materials43,57,58,59,60. Ensure that the Biogas power plant has access to various sources of organic waste, including agricultural, livestock, and household waste. This can reduce dependence on one type of raw material. Establish long-term agreements with organic waste suppliers, such as farms or other food processing plants, to ensure a stable supply of raw materials. Build biogas storage facilities to cope with fluctuations in production and provide a stable electricity supply.

High maintenance rate

Hybrid systems involving Biogas power plants and wastewater treatment require complex and continuous maintenance. Biogas systems require regular maintenance to ensure the digester functions appropriately, while anaerobic wastewater treatment systems require periodic maintenance and replacement.

To address this shortage, ensure that the workforce operating the system has received adequate training on how to perform routine maintenance and handle technical issues17,61,62,63. Creation of a regular maintenance schedule to ensure all components (digesters, generators, filters, sedimentation tanks, etc.) remain in optimal function. Maintenance management software can help track when equipment needs to be inspected or replaced—proper Preventive and Curative Maintenance Implementation. Invest in high-quality, durable components, particularly for tanks and waste treatment systems, to reduce maintenance frequency.

High initial costs

Another drawback of this hybrid system is that it requires a significant initial investment to build biogas infrastructure, power generators, and water treatment plants. This can hinder small-scale implementation or in areas with limited budgets.

Seeking funding from governments, international institutions, or organizations that support renewable energy projects can be a solution. In many countries, there are subsidy programs for renewable energy and waste management17,64,65. Start small and grow gradually so the initial cost is less burdensome. For example, start with small-scale electricity production from biogas before expanding capacity. Partnering with industries that generate large amounts of organic waste can reduce operational costs, as they can share the burden of investment and management.

Instability of energy supply

Biogas power plants can generate electricity unsteadily if the biogas supply fluctuates or the digester has a technical glitch. This instability can be a problem for electricity users requiring a constant supply. The solution to this problem can be to integrate Biogas power plant with energy storage systems, such as batteries, to stabilize the electricity supply during periods of fluctuations in biogas production66,67,68. We are combining Biogas power plants with other renewable energy sources, such as solar panels or wind, to provide energy reserves when biogas production is insufficient. Carry out preventive maintenance to prevent system failures and operational disruptions in biogas power plants.

Technology and innovation challenges

Hybrid technologies like this require continuous innovation to improve efficiency, especially in terms of wastewater treatment from biodigesters and the stability of electricity production from biogas14,69,70. Partner with universities or research institutes to continuously develop and improve water and biogas treatment technologies. Conduct periodic technology evaluations to identify opportunities for efficiency improvement. Use data from daily operations to develop the technology further.

Conclusion

The hybrid system that integrates a biogas power plant and an on-grid power source presents a promising solution for simultaneously addressing energy generation and sustainable energy management. This system has the potential to generate renewable energy from biogas, reduce greenhouse gas emissions, and treat wastewater for reuse, creating a more sustainable and circular approach to resource management.

However, its implementation has challenges and weaknesses, such as reliance on a stable supply of organic waste, variability in wastewater quality, high initial costs, and the need for regular maintenance. Strategic approaches can address these challenges, such as diversifying feedstock, enhancing real-time monitoring systems, leveraging government subsidies, and integrating energy storage for a stable electricity supply.

Moreover, the system offers significant potential in carbon trading, where reducing greenhouse gas emissions—both CO2 and CH₄—can generate additional revenue, enhancing the overall return on investment (ROI). Future research should focus on optimizing biogas production, improving water treatment technologies, integrating with other renewable sources, and exploring carbon trading mechanisms.

Data availability

The data that support the findings of this study are present in the paper is available from the corresponding author Ahmad Nahwani upon reasonable request.

References

-

Elizabeth Funmi, A., Abiodun Suleiman, M. & Inioluwa Deborah, O. Tofunmi Dorcas, A. Biogas production as energy source and strategy for managing waste and climate change. SN Appl. Sci. 3, 1–11 (2021).

-

Tajpour, M., Hosseini, E. & Mohiuddin, M. Effects of innovative climate, knowledge sharing, and communication on sustainability of digital start-ups: Does social media matter? J. Open Innov. Technol. Mark. Complex. 9, 100053 (2023).

-

Nehra, M. & Jain, S. Feasibility assessment of biomass for sustainable power generation to mitigate climate change in a rural cluster: a case study in India. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-023-04351-1 (2023).

-

Tran, H. P., Luong, A. D., Van, A. D. & Nguyen, T. T. A. Energy crop as an environmentally sustainable reclamation option for post-mining sites: a life cycle assessment of cassava planting in Vietnam. Environ. Sci. Pollut. Res. 29, 6722–6732 (2022).

-

Osman, A. I. et al. Cost, environmental impact, and resilience of renewable energy under a changing climate: a review. Environ. Chem. Lett. 21, 741–764 (2022).

-

Pal, D. B. & Tiwari, A. K. Hydrogen Production by Utilizing Bio-Processing Techniques https://doi.org/10.1007/978-981-16-1862-8_7 (2021).

-

Repinc, S. K. et al. Full-scale agricultural biogas plant metal content and process parameters in relation to bacterial and archaeal microbial communities over 2.5 year span. J. Environ. Manag. 213, 566–574 (2018).

-

Vargas-Estrada, L. et al. A review on current trends in biogas production from microalgae biomass and microalgae waste by anaerobic digestion and co-digestion. Bioenergy Res. 15, 77–92 (2022).

-

Irawan, D. & Suwanto, E. Pengaruh Em4 (effective microorganisme) Terhadap Produksi Biogas Menggunakan Bahan Baku Kotoran Sapi. Turbo J. Progr Stud. Tek Mesin 5, 44–49 (2017).

-

Ahou, Y. S., Angeli, B., Awad, J. R., Baba-Moussa, S., Andres, Y. & L. & Assessment of Inoculum to substrate ratio to recover energy from cassava wastes through anaerobic digestion. Waste Biomass Valoriz. 12, 1891–1900 (2021).

-

Hasan, G., Mazancová, J. & RoubÃk, H. Assessment of the incubating environment for investment in biogas technology in Syria by using AHP and SWOT. Environ. Dev. Sustain. https://doi.org/10.1007/s10668-023-03137-9 (2023).

-

Zadgaonkar, L. A., Darwai, V. & Mandavgane, S. A. The circular agricultural system is more sustainable: emergy analysis. Clean. Technol. Environ. Polic. 24, 1301–1315 (2022).

-

Cañote, S. J. B. et al. Energy and economic evaluation of the production of biogas from anaerobic and aerobic sludge in Brazil. Waste Biomass Valoriz. 12, 947–969 (2021).

-

Butemann, H. & Schimmelpfeng, K. Long-term electricity production planning of a flexible biogas plant considering wear and tear. J. Bus. Econ. 90, 1289–1313 (2020).

-

Martinov, M. et al. Assessing sustainable biogas potentials—case study for Serbia. Biomass Convers. Biorefinery 10, 367–381 (2020).

-

Ceylan, A. B. et al. A new hybrid approach in selection of optimum establishment location of the biogas energy production plant. Biomass Convers. Biorefinery 5771–5786. https://doi.org/10.1007/s13399-021-01532-8 (2021).

-

Budiman, I. The complexity of barriers to biogas digester dissemination in Indonesia: challenges for agriculture waste management. J. Mater. Cycles Waste Manag. 23, 1918–1929 (2021).

-

Abbas, I. et al. Development and performance evaluation of small size household portable biogas plant for domestic use. Biomass Convers. Biorefinery 12, 3107–3119 (2022).

-

Erraji, H., Asehraou, A., Tallou, A. & Rokni, Y. Assessment of biogas production and fertilizer properties of digestate from cow dung using household biogas digester. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-023-03818-5 (2023).

-

Verner, V. et al. Economics and perception of small-scale biogas plant benefits installed among peri-urban and rural areas in central Vietnam. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-021-02122-4 (2021).

-

Zaki Dizaji, H. et al. An investigation on the environmental impacts and energy efficiency of biogas and bioethanol production from sugarcane and sugar beet molasses: A case study. Energy Sources Part. Recover Util. Environ. Eff. 00, 1–15 (2021).

-

Kongchouy, P., Tia, W., Nathakaranakule, A. & Soponronnarit, S. Assessment of seasonal availability and spatial distribution of bio-feedstock for power generation in Thailand. Bioenergy Res. 14, 70–90 (2021).

-

Zhou, J. et al. A Current perspective on the renewable energy hydrogen production process. J. Therm. Sci. 32, 542–596 (2023).

-

Alrawad, M., Lutfi, A., Almaiah, M. A. & Elshaer, I. A. Examining the influence of trust and perceived risk on customers intention to use NFC mobile payment system. J. Open Innov. Technol. Mark. Complex. 9, 100070 (2023).

-

Risien, J., Hoke, K., Storksdieck, M., Davis, C. & Klein, E. A dynamic framework for making sense of partnerships between universities and informal education providers. Eval. Program. Plann. 100, 102328 (2023).

-

van der Velden, R. et al. Closed-loop organic waste management systems for family farmers in Brazil. Environ. Technol. (United Kingdom) 43, 2252–2269 (2022).

-

Aklilu, E. G. & Waday, Y. A. Optimizing the process parameters to maximize biogas yield from anaerobic co-digestion of alkali-treated corn stover and poultry manure using artificial neural network and response surface methodology. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-021-01966-0 (2021).

-

Okwu, M. O., Samuel, O. D., Ewim, D. R. E. & Huan, Z. Estimation of biogas yields produced from combination of waste by implementing response surface methodology (RSM) and adaptive neuro-fuzzy inference system (ANFIS). Int. J. Energy Environ. Eng. 12, 353–363 (2021).

-

Sharma, H. & Dhir, A. Response surface methodology for optimization of dry oxidative reforming for hydrogen enrichment of biogas. Biomass Convers. Biorefinery 13, 2875–2883 (2023).

-

Amo-Aidoo, A., Hensel, O., Korese, J. K., Abunde Neba, F. & Sturm, B. A framework for optimization of energy efficiency and integration of hybridized-solar energy in agro-industrial plants: Bioethanol production from cassava in Ghana. Energy Rep. 7, 1501–1519 (2021).

-

Abanades, S. et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 19, 3377–3400 (2022).

-

Baştabak, B. & Koçar, G. A review of the biogas digestate in agricultural framework. J. Mater. Cycles Waste Manag. 22, 1318–1327 (2020).

-

Gernert, M., Schuber, A. & Schaller, A. Experiences in the application of logic models in the context of workplace health promotion – a focus group study. Popul. Med. 5, 526–526 (2023).

-

Gernert, M., Schuber, A. A. & Schaller, A. Experiences in the application of logic models in the context of workplace health promotion – A focus group discussion. Eval. Program. Plann. 100, (2023).

-

Marra, M. & Editorial Eval. Program. Plann. 100, (2023).

-

Srivichai, P. & Chavalparit, O. Optimization of biogas production from codigestion of waste activated sludge and modified tapioca starch sludge. Int. J. GEOMATE 18, 148–155 (2020).

-

Brar, K. K. et al. A paradigm shift towards production of sustainable bioenergy and advanced products from Cannabis/hemp biomass in Canada. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-022-02570-6 (2022).

-

Mofijur, M. et al. Bioenergy recovery potential through the treatment of the meat processing industry waste in Australia. J. Environ. Chem. Eng. 9, 105657 (2021).

-

Tagwi, A. & Chipfupa, U. Participation of smallholder farmers in modern bioenergy value chains in Africa: Opportunities and constraints. Bioenergy Res. 16, 248–262 (2023).

-

Suhartini, S. et al. Food waste to bioenergy: current status and role in future circular economies in Indonesia. Energy Ecol. Environ. 7, 297–339 (2022).

-

Le, T. T., Doan, X. H. & Duong, C. D. A serial mediation model of the relation between cultural values, entrepreneurial self-efficacy, intentions and behaviors: Does entrepreneurial education matter? A multi-group analysis. J. Open Innov. Technol. Mark. Complex. 9, 100064 (2023).

-

Cherukuri, N. R. & Parthasarathy, P. Influence of compositional and structural characteristics on food waste for biogas production. Int. J. Environ. Sci. Technol. https://doi.org/10.1007/s13762-023-05004-6 (2023).

-

Arbain, A., Gewe, S., Raharjo, R., Iskandar, R. & S. & The study of potential biogas formation from food waste and co-substrates of cow feces for alternatives electrical energy: Case study In Andalas University. J. Litbang Ind. 5, 101–111 (2015).

-

Freitas, F. F. et al. Study of the potential for energy use of biogas from a wastewater treatment plant to a medium-sized city: A technical, economic and environmental analysis. Waste Biomass Valoriz. 13, 3509–3521 (2022).

-

Patel, A., Gami, B., Patel, B., Parmar, V. & Patel, P. Cost benefit and environmental impact assessment of compressed biogas (CBG) production from industrial, agricultural, and community organic waste from India. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-022-02780-y (2022).

-

Roy, P., Ahmed, M. A. & Shah, M. H. Biogas generation from kitchen and vegetable waste in replacement of traditional method and its future forecasting by using ARIMA model. Waste Dispos. Sustain. Energy 3, 165–175 (2021).

-

Dell’Omo, P. P. & Spena, V. A. Mechanical pretreatment of lignocellulosic biomass to improve biogas production: Comparison of results for giant reed and wheat straw. Energy 203, 117798 (2020).

-

Nurgaliev, T., Koshelev, V. & Müller, J. Simulation model for biogas project efficiency maximization. Bioenergy Res. 1084–1098. https://doi.org/10.1007/s12155-022-10484-4 (2022).

-

Hasan, G., Mazancová, J., Banout, J., Jafar, R. & RoubÃk, H. Feasibility analysis of small-scale biogas plants usage in the Syrian coast through agricultural crop residues and co-digestion of manure. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-021-02112-6 (2022).

-

Xu, X. et al. Circular economy pattern of livestock manure management in Longyou, China. J. Mater. Cycles Waste Manag. 20, 1050–1062 (2018).

-

Siddiki, S. Y. A. et al. Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J. Environ. Chem. Eng. 9, 105204 (2021).

-

Senpong, C. & Wiwattanadate, D. Krabi’s renewable energy transition towards sustainable energy: drivers, barriers, and challenges. Environ. Dev. Sustain. https://doi.org/10.1007/s10668-023-02986-8 (2023).

-

Obaideen, K. et al. Biogas role in achievement of the sustainable development goals: Evaluation, challenges, and guidelines. J. Taiwan Inst. Chem. Eng. 131, 104207 (2022).

-

Mokraoui, S., Halilu, A., Hashim, M. A. & Hadj-Kali, M. K. Modeling and simulation of biomass anaerobic digestion for high biogas yield and CO2 mineralization. Mater. Renew. Sustain. Energy https://doi.org/10.1007/s40243-023-00233-8 (2023).

-

Rivera-Montenegro, L., Valenzuela, E. I., González-Sánchez, A., Muñoz, R. & Quijano, G. Volatile methyl siloxanes as key biogas pollutants: Occurrence, impacts and treatment technologies. Bioenergy Res. 801–816. https://doi.org/10.1007/s12155-022-10525-y (2022).

-

Kapoor, R., Ghosh, P., Kumar, M. & Vijay, V. K. Evaluation of biogas upgrading technologies and future perspectives: a review. Environmental Science and Pollution Research (Environmental Science and Pollution Research, 2019). https://doi.org/10.1007/s11356-019-04767-1

-

Aristizábal-Marulanda, V., Solarte-Toro, J. C. & Cardona Alzate, C. A. Study of biorefineries based on experimental data: production of bioethanol, biogas, syngas, and electricity using coffee-cut stems as raw material. Environ. Sci. Pollut. Res. 28, 24590–24604 (2021).

-

Siqueira, M. U. et al. Brazilian agro-industrial wastes as potential textile and other raw materials: a sustainable approach. Mater. Circ. Econ. 4, (2022).

-

Varna Vishakar, V., Kumar, S. & Kumar, A. Design and analysis of biogas plant for the institutional campus. Mater. Today Proc. 69, 1498–1500 (2022).

-

de Oliveira, L. R. G., dos Santos Filho, D. A., Fraga, T. J. M. & Jucá, J. F. T. da Motta Sobrinho, M. A. Kinetics assessment and modeling of biogas production by anaerobic digestion of food wastes and acclimated sewage sludge. J. Mater. Cycles Waste Manag. 23, 1646–1656 (2021).

-

Peters, R. et al. Thermodynamic and ecological preselection of synthetic fuel intermediates from biogas at farm sites. Energy Sustain. Soc. 10, (2020).

-

Guilayn, F., Rouez, M., Crest, M., Patureau, D. & Jimenez, J. Valorization of digestates from urban or centralized biogas plants: a critical review. In Reviews in Environmental Science and Biotechnology (Springer, 2020).

-

Ali, S., Yan, Q., Razzaq, A., Khan, I. & Irfan, M. Modeling factors of biogas technology adoption: a roadmap towards environmental sustainability and green revolution. Environ. Sci. Pollut. Res. 30, 11838–11860 (2023).

-

Franqueto, R., da Silva, J. D., Starick, E. K. & Jacinto, C. F. Anaerobic codigestion of bovine manure and banana tree leaf: the effect of temperature variability on biogas yield in different proportions of waste. J. Mater. Cycles Waste Manag. 22, 1444–1458 (2020).

-

Andriamanohiarisoamanana, F. J. et al. Anaerobic co-digestion: a sustainable approach to food processing organic waste management. J. Mater. Cycles Waste Manag. 22, 1501–1508 (2020).

-

Mozhiarasi, V. et al. Variations in generation of vegetable, fruit and flower market waste and effects on biogas production, exergy and energy contents. J. Mater. Cycles Waste Manag. 21, 713–728 (2019).

-

Han, R. et al. The effect of temperature fluctuation on the microbial diversity and community structure of rural household biogas digesters at Qinghai Plateau. Arch. Microbiol. 202, 525–538 (2020).

-

Saracevic, E., Woess, D., Theuretzbacher, F., Friedl, A. & Miltner, A. Techno-economic assessment of providing control energy reserves with a biogas plant. Front. Chem. Sci. Eng. 12, 763–771 (2018).

-

Gaibor-Chávez, J., Niño-Ruiz, Z., Velázquez-MartÃ, B. & Lucio-Quintana, A. Viability of biogas production and determination of bacterial kinetics in anaerobic co-digestion of cabbage waste and livestock manure. Waste Biomass Valoriz. 10, 2129–2137 (2019).

-

Koyani, K., Shah, M., Parikh, S. P. & Shah, D. A systematic study on simulation and modeling of a solar biogas reactor. Environ. Sci. Pollut. Res. 44378–44399. https://doi.org/10.1007/s11356-022-24418-2 (2023).

Acknowledgements

The authors are grateful to the Interdisciplinary School of Management & Technology, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia. Furthermore, thankful to the Department of Civil Engineering, Faculty of Engineering and Science, University of Muhammadiyah Bangka Belitung for contributing to the latest and up-to-date literature related to this research problem and PT Bangka Asindo Agri (BAA), an Agro-Industrial Company that has a processing Tapioca and Sago Flour located on the West Ring Road, Kenanga, Sungailiat District, Bangka Regency, Bangka Belitung Province.

Author information

Authors and Affiliations

Contributions

Author’s contributions to the manuscript, “Strategic Model for Integrating Biogas in Agro-Industry: A Framework for Sustainable Energy Integration in Agro-Industries.� Ahmad Nahwani Led the conceptual framework design and methodology development for this study. He was responsible for conducting the functional analysis, assessing the economic feasibility of biogas integration, and performing the ROI calculations. Additionally, he contributed to drafting and revising the manuscript and coordinated the collaboration among the co-authors. Soeprijanto Prof. Soeprijanto contributed extensively to the technical aspects of the biogas system integration, including the design and optimization of the hybrid system modules. He provided insights on renewable energy strategies, oversaw the environmental impact analysis, and contributed to the manuscript’s literature review, particularly on the topics of sustainable energy and carbon trading. Erwin Widodo Dr. Erwin Widodo focused on the data modeling, statistical analysis, and interpretation of the research findings. He managed the technical aspects of the Automatic Transfer Switch (ATS) module and the System Advisory Model (SAM). Additionally, he reviewed the final draft for technical accuracy, ensuring alignment with the study’s objectives and provided significant input to the discussion and conclusion sections. Together, the authors collaborated to create a comprehensive model and detailed manuscript that addresses the integration of biogas in agro-industries as a sustainable energy solution. Each author contributed their specific expertise, ensuring a well-rounded and robust study.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Nahwani, A., Soeprijanto, S. & Widodo, E. Strategic model for integrating biogas a framework for sustainable energy integration in agro-industries.

Sci Rep 14, 31515 (2024). https://doi.org/10.1038/s41598-024-83181-1

-

Received: 07 October 2024

-

Accepted: 12 December 2024

-

Published: 28 December 2024

-

DOI: https://doi.org/10.1038/s41598-024-83181-1

Keywords

Search

RECENT PRESS RELEASES

Related Post